rockwell hardness test steel 8640 4042 1040|rockwell hardness test accuracy : importers The results of the experiment revealed that sample EN-3 (~1015) produces 87 HRC hardness value at 9.0 mm position at the start and 50 HRC at the position of 97.3 mm, likewise EN-8 (~1040) produces . 25 de dez. de 2023 · Alessandra Negrini compartilhou uma mensagem sobre gratidão no Natal, celebrado nesta segunda-feira (25), por meio das suas redes sociais. A atriz divulgou um vídeo agradecendo os fãs pelo .

{plog:ftitle_list}

Resultado da Obtenha aplicativos, jogos e muito mais para seu dispositivo Windows

rockwell surface hardness test

AISI 8640 Steel, cold drawn, 25 mm (1 in.) round. Subcategories: Alloy Steel; AISI 8000 Series Steel; Low Alloy Steel; Carbon Steel; Medium Carbon Steel.Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

tearing test download

Rockwell hardness test steps. Advantages and disadvantages of hardness testing using the Rockwell method. The Rockwell method offers the following advantages: No specimen preparation required (cutting, grinding, embedding) . The results of the experiment revealed that sample EN-3 (~1015) produces 87 HRC hardness value at 9.0 mm position at the start and 50 HRC at the position of 97.3 mm, likewise EN-8 (~1040) produces .The inflection point (Fig. 4.18 for SAE 1040 steel) on this hardness versus distance curve usually corresponds to 50% martensite and is used as a measure of hardenability of the steels, or, knowing the carbon content, and thus, the hardness of 50% martensitic structure from Fig. 4.1, and then drawing a horizontal line at this hardness (HR C 43 .

AISI 1040 Steel, oil quenched from 855°C (1570°F), 595°C (1100°F) temper, 13 mm (0.5 in.) round . Hardness, Rockwell B, Converted from Brinell; Hardness, Rockwell C, Converted from Brinell hardness. Value below normal HRC range, for comparison purposes only.Key-Words: - AISI 1040 Steel, Hardness, Vickers, Heat Treatment. Received: May 27, 2022. Revised: April 11, 2023. Accepted: May 17, 2023. Published: June 9, 2023. . analyzed at the Hardness Test Laboratory (Rockwell) located at the Mechanical Engineering Department of Muhammadiyah Purwokerto University. Figure 3. AISI 1040 Steel 3.1. Research .

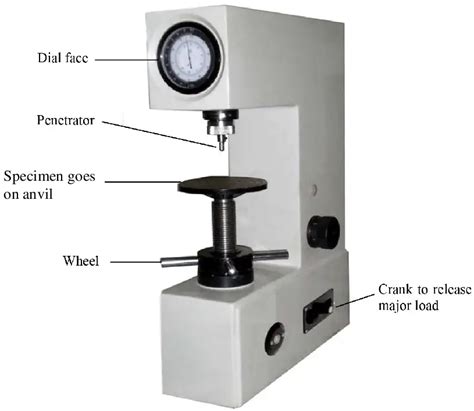

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to Brinell hardness. However, the Rockwell test uses a diamond indenter or a hardened steel ball and a different measurement method. Test procedure: Sample .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf . 1722: R. A. Réaumur develops a method of scratching the surface of minerals using steel. 1822: The Mohs scale for mineral testing is invented. This . The Rockwell hardness test measures a number which depends on the difference in the depth of an indentation made by two loads, a minor load followed by a major load. There are different scales for the Rockwell hardness test. For example, the commonly used Rockwell C test uses a minor load of 10 kg, followed by a major load of 150 kg.5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.

hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which isSAE AISI 4140 Alloy Steel. SAE 4140 (AISI 4140 steel) is a Cr-Mo series (Chrome molybdenum series) low alloy steel, the material has high strength and hardenability, good toughness, small deformation during quenching, high creep strength and long-lasting strength at high temperature. 4140 Steel Uses. AISI SAE 4140 alloy steel can be made into round steel bar, flat & square .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

Here’s a breakdown of the different Rockwell scales and which materials they’re applied on: Scale A – Cemented carbides, shallow case hardened steel and thin steel; Scale B – Soft steels, malleable iron, copper alloys, aluminum alloys, .The following datasheet provides details about AISI 4042 alloy steel. Chemical Composition. The following table shows the chemical composition of AISI 4042 alloy steel. Element Content (%) Iron, Fe: 97.93-98.55: Manganese, Mn: . Hardness, Rockwell B (converted from Brinell hardness) 93: 93:These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

Rockwell A (HRA) Thin steel and carbide: 60 kgf: Rockwell B (HRB) Softer metals like copper alloys, aluminum, and soft steels . Harder materials like hardened steel and titanium alloys: 150 kgf: Rockwell Methodology. The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .AISI 8640 Steel, quenched 845°C (1550°F), 540°C (1000°F) temper . Hardness, Vickers, Converted from Rockwell C hardness. Modulus of Elasticity, Typical for steel; Bulk Modulus, Typical for steel. Poissons Ratio, Calculated; Machinability, annealed and cold drawn. Based on AISI 1212 steel = 100%.test force. 3.1.7 Rockwell hardness machine—a machine capable of performing a Rockwell hardness test and/or a Rockwell super-ficial hardness test and displaying the resulting Rockwell hardness number. 3.1.7.1 Rockwell hardness testing machine—a Rockwell hardness machine used for general testing purposes.

All three steels were processed using water quenching. Of the steels shown, 8640 has the highest surface hardness, which is approximately 31 Rockwell C. Millimeters 20 30 10 0 60 40 50 50 8640 Rockwell C hardness 30 4042 20 1040 10 0 8 16 24 Sixteenths of an inch 32Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to . The rockwell hardness test is commonly used to measure the hardness of steel, which is crucial for kitchen knives. . Understanding How Carbon Steel Knives Fare In Rockwell Hardness Tests. Carbon steel knives have gained popularity among culinary enthusiasts for their exceptional sharpness and edge retention. Here’s what you need to know . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . The majority of applications are covered by the Rockwell C and B scales for testing steel, brass and other metals. However, the increasing use of materials other than steel and brass, as well as thin materials, necessitates a basic knowledge of the .

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

rockwell hardness testing standards

rockwell hardness testing procedure

tearing test for fabric

rockwell hardness testing advantages

Review of Races and Aces Henderson | Best Casinos in Breaux Bridge, Louisiana. . Races and Aces Henderson Review; Casino info . 2939 Grand Point Hwy , Breaux Bridge , 70517 , USA (337) 667-7095. site. Casino info. Owner: Total Gaming Space: 225 .

rockwell hardness test steel 8640 4042 1040|rockwell hardness test accuracy